Hand Tapping Machine

(Originally from here)

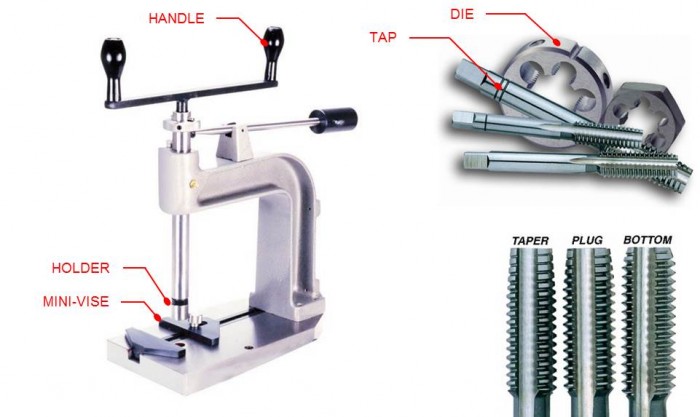

The Shop in Bray Lab has a hand tapping machine that can be used to create threaded holes in metals like steel, brass, aluminum, or cast iron depending on the bit used.

Setup

- Internal threading is done by using a tool called a TAP

- Tapping is done on a hole that is pre-drilled for a specific thread size and pitch to be

cut - External threads (for bolts) are made using a DIE, which is applied to a specified

diameter of rod for the specified size and pitch to be cut - Select proper hand tap (taper, plug, bottoming) and fit it into a holder

- Align pre-drilled workpiece under tap (can use mini-vise to hold part)

Safe Operation

- Turn handle clockwise to start thread (back up every 1-2 turns to break forming chip)

- Use lubricant to assist the thread-cutting

- Taps can be brittle, so be careful not to bind the tap or break it

Cleanup

- If a tap or threaded piece needs cleaning with compressed air, protect your eyes with

proper protection (do NOT endanger person in the area near you - Use a brush or piece of cloth to remove chips, NOT your hand

- Clean table, floor, and surrounding work area