CNC Routing

This (in-progress) page is intended to serve as an introduction to the basics of CNC routing for students interested in using CNC routers at Tufts. At the moment, Bray Lab's ShopBot CNC Router is the only one available for students to complete personal or school-related projects.

What is a CNC Router?

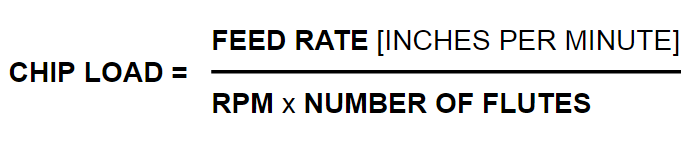

A Computer Numeric Control, or "CNC", Router is a computer-operated milling machine. They have three operational axes and can read both 2D .dxf files and 3D .stl files. They can be used for many different projects that include, but are certainly not limited to, milling, drilling, carving, positive and negative molding, and furniture design.

Milling

Negative Molding

Positive Molding

Furniture Design

How do CNC Routers work?

CNC Routers typically operate on 3 axes and have a drill bit that takes away material as it moves forwards, backwards, side to side, and up and down through the workspace. A computer program called VCarve Pro is often used to control the path that the machine follows while cutting. Different toolpaths can be combined to achieve the best possible finished product. For example, a "roughing" toolpath can be used first to take out the majority of material and leave a rough shape of the final product. Then, a "finishing" toolpath can be used to go back over the material to clean up the surfaces and add fine details.

What materials can be cut with a CNC router?

It depends on the router being used, but in general, CNC routers can cut:

- Solid wood

- Plywood

- MDF

- Most plastic sheets

- XPS foam

For safety reasons, the following materials can't be used at Tufts:

- Pressure-treated wood

- Stained or painted wood

- Any metal

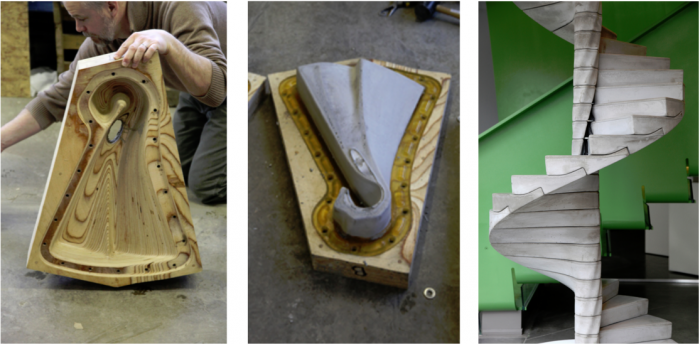

Different drill bits can be used for the different toolpaths. An end mill bit (second from the left) is good for hogging out lots of material during a roughing toolpath. A ball nose bit can be used for the finishing path because of its finer and more versatile shape.

Types of Bits

End Mill: good for straight cuts and for hogging out a lot of material (ie. for a roughing toolpath)

Ball-Nose: good for contours, details, and finishing paths

Profile (such as a V-Carve): good for lettering and sign-making

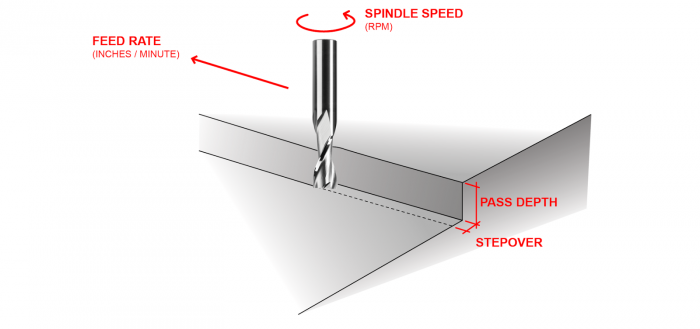

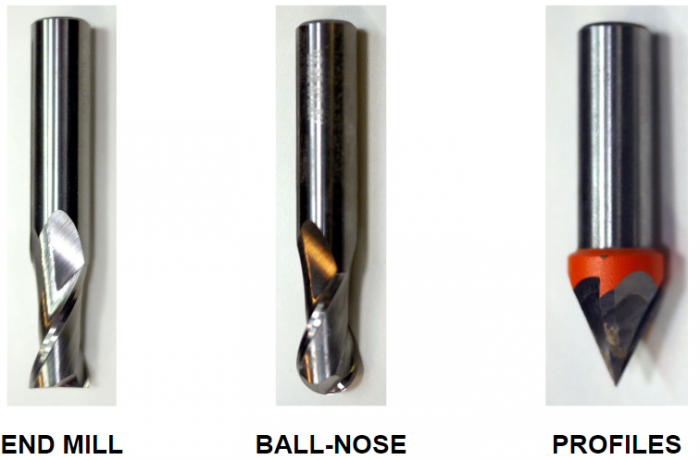

Feeds and Speeds

Feed is the linear feed of the tool through the material

Speed is the rotational frequency of the spindle which turns the bit

The feeds and speeds are defined for each bit and material type within the toolpathing software. Feeds and speeds vary for each machine (due to available spindle power), material type and the environment (temperature, humidity).