Oreo De-creamer

Start with something small

When our group met with Dan Hannon to discuss the idea of starting a new product and making-oriented club, he suggested that we test out the idea with something small and fun. A video of an Oreo cookie separator was floating around the internet at the time, so we decided to start with that.

We started this project at a time when making things at Tufts was pretty difficult for underclassmen. What materials did we have available at Tufts? How much would a typical project cost? What tools could we use? Would our design process work? Was it fun? Could we use the laser cutter? The 3D printers? Wood? Cardboard?

We didn’t really know, which is why we decided to dive right in with a project of our own. A semi-pointless one. Something that wasn’t dangerous, could be done in a bunch of different ways, and would take both engineering and design work to finish.

We decided to de-cream an Oreo.

How might we?

This Oreo de-creamer project was a way of testing out making things at Tufts. We wanted to see if a club focused on product design and making things was feasible or not, and whether or not there was any value in pursuing it.

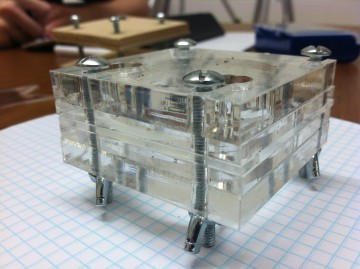

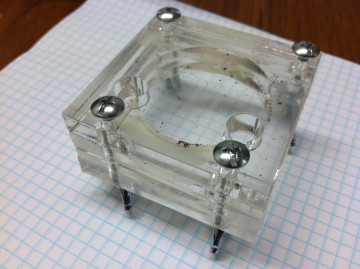

Our final Oreo de-creamer prototype, despite being impractical and kinda messy, is therefore more of a trophy than anything else; a visual reminder of what we were able to do with no experience, no resources, very little funding, and only a sophomore level of experience with the school.

It may sound sappy, but through this project we realized that the journey or the process of making something is often more important than the final product you create.

That’s when it clicked in our heads. Yes, a product design club could work at Tufts, because whether or not the devices students created became businesses or valuable solutions, the learning that happens is unlike anything else taught at Tufts University.

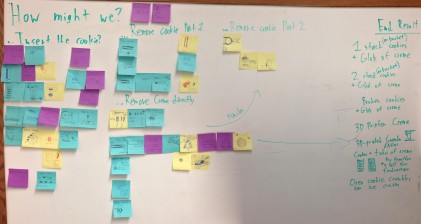

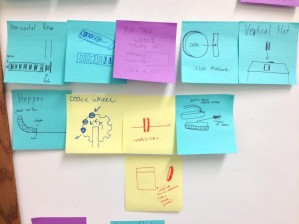

Brainstorming

Experimenting

We needed to find the cleanest way of separating cookie from cream. Some of our ideas during brainstorming involved melting and slicing Oreos, so we decided to test those ideas to see which method was most effective.

Could we melt the cream away?

No, not really. The sugary cream and the outer cookie see to have similar melting points, so separating them with heat isn't easy. Using an open flame wasn't effective at all, and the microwave ended up melting just as much cookie as cream.

Could we twist the cookies off the cream?

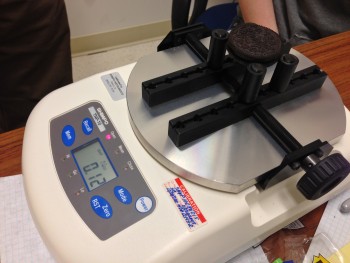

Sort of. The cream of an Oreo tends to be more stuck to one cookie than the other, probably as a result of its manufacturing process. We used a measuring device to quantify the torsion force required to twist the cream off the cookie, and although one of the two cookies would usually come off pretty cleanly, predicting which cookie that would be wasn't possible. Without being able to know which cookie half would end up with cream stuck to it, we passed on this method.

Could we slice the cream off the cookie?

Yes, mostly. We tried cutting off the cream with a scalpel, and although it left some cream behind (a larger, straight-edge razer blade likely would've worked better) the result was more consistent and effective than the other two methods.

We figured that if our device could reliably slice/cut/push away the cream between the two cookies, that would be the most effective way to de-cream an Oreo.

Prototyping

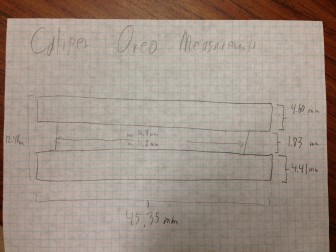

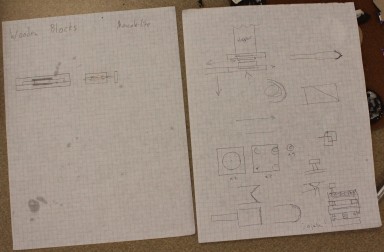

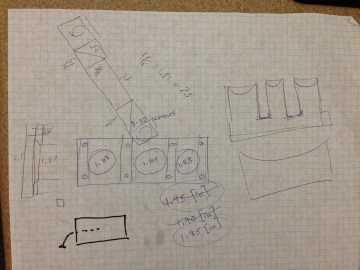

Sketching and measuring

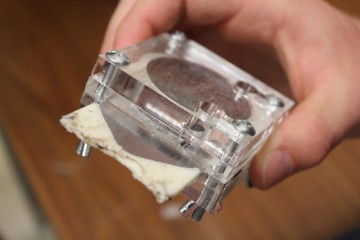

Our team noticed that although the width of cream between two Oreos can vary cookie-to-cookie, the cookie width is generally consistent. We bought a bunch of Oreos and started to measure their dimensions.

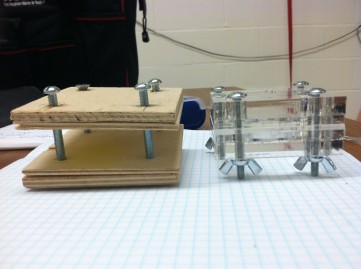

We then started building an initial proof of concept prototype out of wood, but without any hand tools available to us, we needed some help.

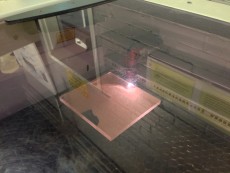

Thanks to our advisor, Dan Hannon, and Jim from the Machine Shop, we were able to visit Bray Lab and use the laser cutter and drill to create our first prototype more quickly.

We then tested it. It worked somewhat well.

Unfortunately the Oreo broke.

And those were our prototypes.

We started working on a third and final prototype that would allow the user to de-cream 3 Oreos at once, but after playing with the second prototype a bit more, we realized that the frictional force would likely be too large/annoying for it to be practical.

Conclusion

This was a fun project that lasted about a month.

We realize that our final prototype isn't the "best" or most reliable way to de-cream an Oreo, but that was never really the point. This project's silly premise allowed us to explore a variety of solutions and ever-so-slightly push the boundary of what students at Tufts are able to make. Nothing we could've made would be commercially viable or even all that useful, which was freeing, in a way.

Through this project, we discovered how difficult it is for Tufts students to get access to the tools and equipment they need to make compelling prototypes for non-course-related projects. We were also able to practice some of the product design techniques we had only read about up until that point, and lean on each other's experience and skills to make something.

Our Oreo de-creamer isn't significant because of what it is, but because of what we learned through making it. It was built at a time when no community makerspaces were available on campus other than the Crafts Center, which hadn't yet undergone its complete transformation into a community-oriented space.